Airsoft Ak 47 Selector Switch Fix

Airsoft Ak 47 Selector Switch Fix

Every bit a Version 3 gearbox owner, yous may have noticed that occasionally y'all get an odd selector switch trouble at present so out of your AK. Granted, these instances are rare and far between, but to the uninitiated they can be frustrating to runway downwards and properly diagnose. This article will evidence yous a few things to look out for. We will as well delve just a bit into the trigger switch assembly likewise, as that is office of the system.

|

Before attempting to diagnose your selector switch issues, first determine whether or not you lot are operating with a fully charged bombardment. While this seems rather obvious, information technology is fairly mutual for folks to overlook this part, and futilely exclaim their gun is cleaved when it is a unproblematic thing of a dead battery.

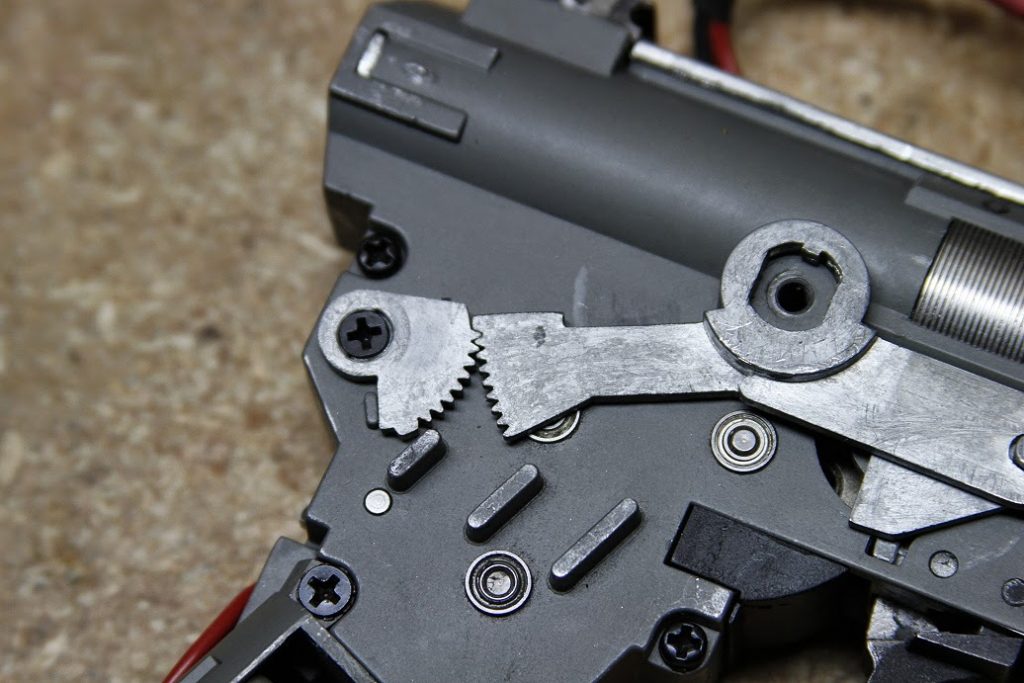

As we are working from the exterior in on this guide, after you lot determine your battery is fine, look immediately at the external selector switch for damage. Occasionally during a game, you might suddenly notice that your external selector switch is stuck and is unable to move from its current position. Earlier you panic, remove the dust cover and take a peak inside the receiver at the internal selector gears as pictured above. A few things can jam these upwardly and forbid their movement, and 1 of those is debris or BB's. If yous reload with your muzzle pointed skyward and your mags practice not take the last circular feed characteristic, you tin occasionally get BB's rolling backwards within the receiver. Sometimes one of these volition get stuck in betwixt the teeth of the selector gears and jam them. This is a pretty rare problem, but I've seen it happen to a number of guns. The quick fix is to but popular out the jammed BB and get back into the game. Depending on how badly the BB is stuck in there, you may or may not have to remove your gearbox from the receiver to dislodge information technology.

|

Another problem with regard to the external and internal selector switches tin can be attributed to "slop" or being worn out, or even built out of spec. Generally slop or wearing out doesn't occur, except in situations where the gun has been heavily used. You tin can unremarkably spot slop by slipping the selector switch to the semi-auto position so slowly (with the top cover removed) examine its travel as you slide it upwards into the full auto position. If while observing this you see that the internal selector gears have non moved, then y'all have show of "slop." With slop, you might have noticed that this is why your AEG no longer works correctly on full automobile when it is engaged in the full auto slot. You may too notice that if you push the selector switch just a touch higher, to where it rests just above the full auto notch, that you can usually engage the full auto mode. If this is the case, either your external selector is out of spec, worn out, or the internal selector switch gears are worn out. More than particularly, the worn out section is where the external selector switch fits into the internal selector gear.

I potential fix is to simply move the internal selector switch up exactly one gear molar (as pictured to a higher place.) With AEG's that have out of spec or very worn exterior selector switches, this has solved 99% of the problems I encounter. Exist warned: on a make new or lightly used AEG, doing this can mean that your semi-machine position is at present a full motorcar position! For guys who want their AEG'south to strictly shoot total auto merely on both selector switch positions, you could conceivably do this. Be sure to fully test for proper function if y'all mess with the selector switch gears.

|

Keeping in mind that nosotros are working on the internal selector gears, you lot should take the time to also examine them for broken or damaged teeth. If this is the instance, you could be experiencing slippage or wrong meshing – which can cause a diversity of problems such as inadvertent full auto in the semi-auto fashion, failure to appoint in the correct fire way, or simply not working.

This besides applies to the left side of the gearbox and the selector switch plate (the plastic office.) On a Version two gearbox, a stripped selector plate is usually the most common issue I've encountered. On a version three, I accept nevertheless to run across a stripped selector plate, but it is a proficient idea to examine this surface area while y'all're digging around.

|

Removing the selector plate next, we volition be looking at the trigger contact surface for harm or burn-through. Again, not a existent common problem. If you lot're shooting an extremely loftier ROF AEG with heavy duty LIPO's with a high C rating you might see this surface area burned out. Typically, all the same, the most yous might see is some slight habiliment and mayhap a fleck of carbon buildup. You tin can scrape the carbon off with a razor blade.

Information technology's also a proficient idea to make certain the selector switch plate can move freely in its track and that zip is bounden or preventing it from moving properly. On some gearboxes I've examined, at that place can be some issues with it dragging badly against the trigger return spring that pokes out of the triangular notch on the left side. Sometimes if these springs have been replaced or are wrong, they can be slightly too long and thus hit the selector switch plate. You can either trim the bound to right length so information technology sits flush with the gearbox, or but radius the corner of the selector switch plate that hits the spring. Doing the latter is sometimes the more preferable and quicker pick.

|

Side by side we are taking a look at the trigger contact switch. Most Version iii designs have a dual contact arrangement – basically 2 tabs that engage the trigger switch plate and complete an electric circuit. These tabs, similar on whatsoever AEG can wind up deformed with time and heavy use. If this happens, they don't aren't necessarily making 100% contact with the trigger switch plate, which can upshot in a non-firing status.

In that location are three ways of fixing this:

- Method #1 is to slightly bend or flex the tabs upwards, away from the gearbox body so they tin can make full contact with the selector switch plate. The biggest trouble with this method is the tabs are very fragile, and if you curve them upward too much, you lot tin can take a chance breaking them off. In which case you'll be looking at a new trigger switch or scrounging for new contacts in your box-o'-scrap-parts.

- Method #two is to build up the surface but a scrap with silver solder. Some guys like to "bridge" both contacts with solder as well. This design, in fact, is what is found on the semi-auto-just SVD. The biggest affair to pay listen with when soldering the contacts is it has to exist washed just right. Too much solder and you lot can crusade excessive friction and binding with your selector switch plate – sometimes even preventing information technology from sliding over the contacts entirely!

- Method #3 is to remove the metal contact from the selector switch plate. This is best accomplished with a dental option. Taking some pliers, give the contact plate merely the tiniest curve, so it forms a slight arch. Doing this will ensure it mates confronting the surface of the trigger switch tabs. As with the above methods, don't ham-fist it. Generally this solves 99% of the not-contact problems I encounter. If they're more than astringent, I would consider the first 2 methods.

|

Moving in deeper, nosotros are now looking at the guts of the trigger switch, including the trigger trolley. What you are looking for in here is evidence of excessive carbon build up, burned out contacts, gunk (including grease, oils, etc.) that are causing bad connexion. Guys who tend to over lube their gearboxes tin can sometimes detect their gearsets have slung gloop into here. You want this surface area to be nice and clean. Nosotros are as well looking for broken wires here too. Equally these are simply soldered on to the yet-over again-fragile trigger contacts, pay attention to not torquing them too much.

Examine the trigger contacts for signs of burnout. This can be hard to spot sometimes, but can manifest every bit a pocket-sized hole, a large section burned off, or a completely dissolved contact. Generally, unless it's truly severe, you tin can get away with a petty burning for awhile yet. On a Ver. three these parts are typically replaceable without having to purchase the unabridged switch assembly. Some other issue tin can exist that y'all take a warped trigger switch – this is something that has been occurring on some LCT guns in particular of late – they merely aren't designed to take the rut generated during sustained firing and thus warp. Friday at the Factory Syndrome can hit whatever airsoft manufacturer, even ones held to high esteem. Fortunately it is a easily fixable problem.

Additional areas to examine: check the 'shelf' on the trigger trolley – this is the flat piece on the left side of the trolley that engages with the cutoff lever. Additionally, yous should also examine the cutoff lever and jump, and ensure these parts are not worn out or cleaved. If the shelf on the trigger trolley is severely gouged or worn out, it will cause issues, every bit will an overly worn cutoff lever.

And there you have it! Without going too much deeper into other issues that could crusade trigger and selector switch related issues, such as tappet plates, cutoff levers, etc. These are generally the most basic and common issues encountered. That being said, the Version 3 selector and trigger design is quite tough, and does not often run across these problems.

Airsoft Ak 47 Selector Switch Fix

Posted by: smithwittleen.blogspot.com

0 Response to "Airsoft Ak 47 Selector Switch Fix"

Post a Comment